Experienced Technical Team & Rich Database

- More than 60 Engineers

- Over one hundred patents

- 25 years experiences in motor industry

- PDMS project management

- Perfect motor laboratory

- Professional design software

- Provide total solution of Motor , Gearbox & Controller(with software)

- Obviously advantages in automotive grade motor and controller

- More than 90% accuracy rate, the fastest-2 month R&D lead time.

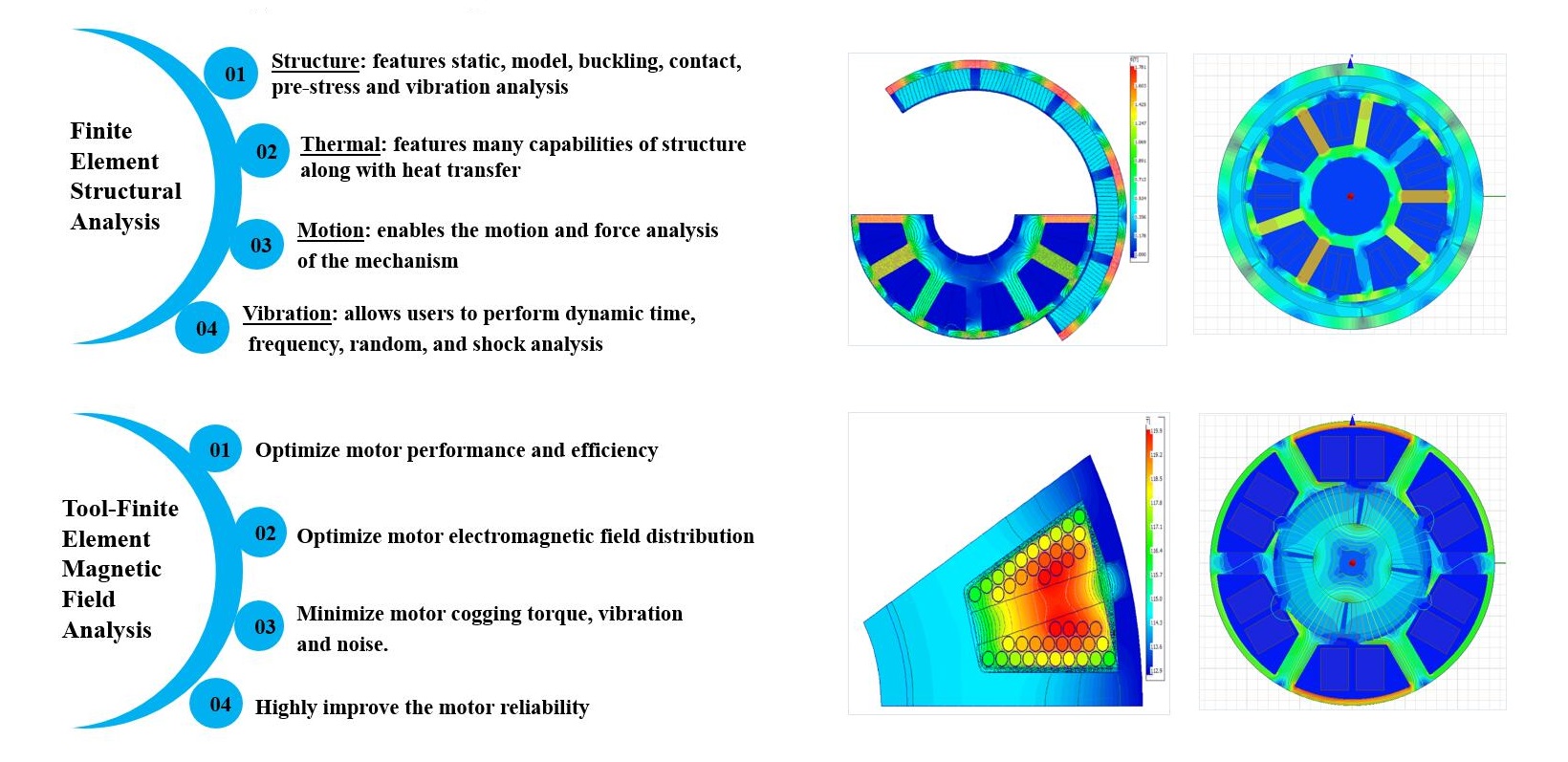

Specific Design Software